Can a safety valve be repaired?

2026-02-09

Content

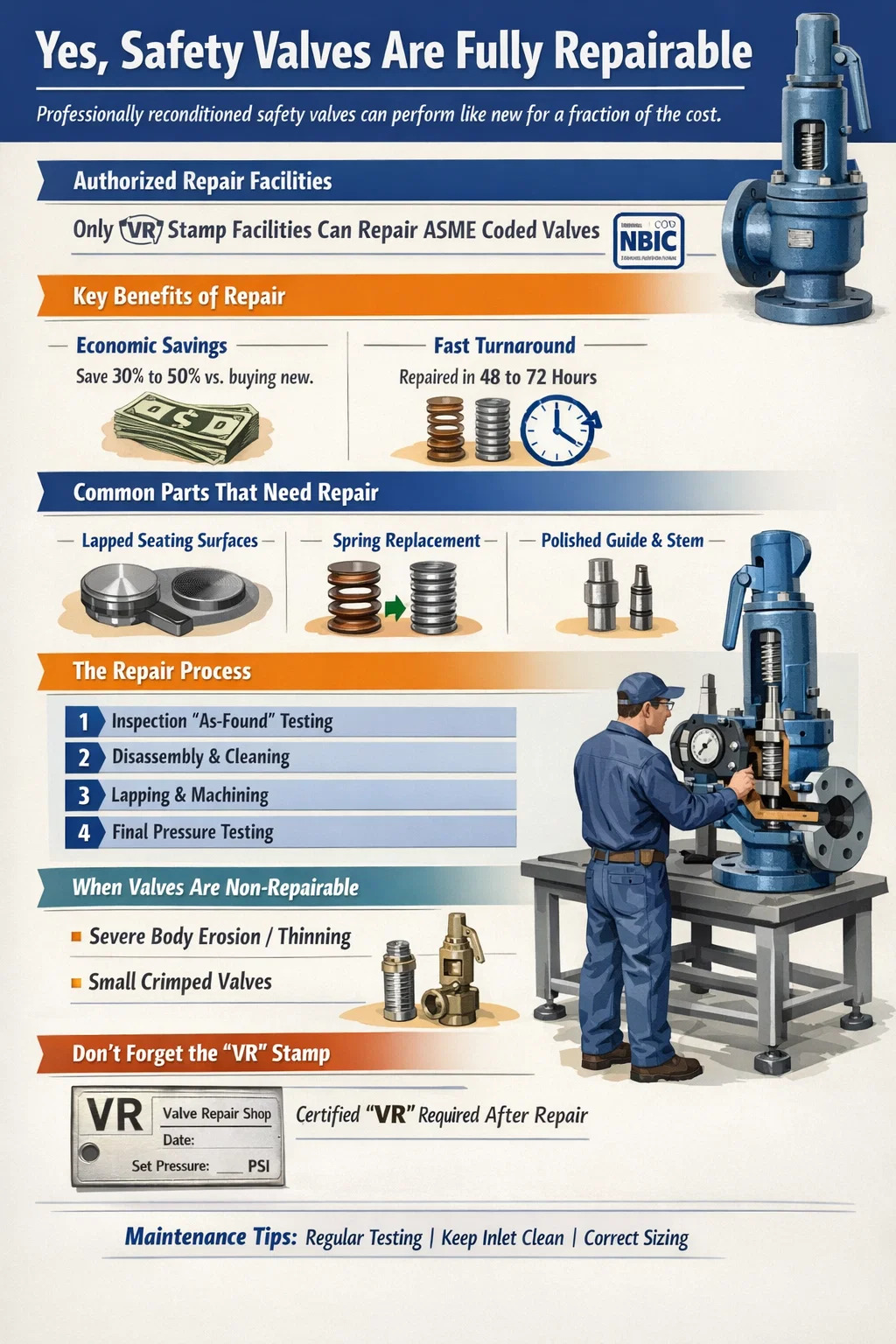

Direct Answer: Yes, Safety Valves Are Fully Repairable

The short answer is yes, a safety valve can be repaired, provided the structural integrity of the valve body remains intact. Unlike many disposable industrial components, safety valves are engineered as heavy-duty precision instruments designed for a long service life. In fact, a professionally reconditioned safety valve can perform exactly like a brand-new unit, often at a fraction of the cost.

However, "repair" in this context is not a simple DIY fix. Because these devices are the final line of defense against catastrophic overpressure, the repair process is governed by strict codes such as the National Board Inspection Code (NBIC) and ASME standards. Only authorized facilities with a "VR" (Valve Repair) stamp are legally permitted to perform these tasks on ASME-coded vessels.

When to Choose Repair Over Replacement

Deciding whether to fix an existing safety valve or buy a new one usually comes down to economics, lead times, and the physical condition of the hardware. For large-bore valves or those made from exotic alloys, repair is almost always the preferred route.

Economic Savings

On average, repairing a safety valve costs between 30% to 50% of the price of a new valve. For an industrial facility managing hundreds of valves, this translates to hundreds of thousands of dollars in annual savings.

Lead Time Advantages

New safety valves from major manufacturers can sometimes have lead times of 12 to 24 weeks. A local authorized repair shop can often strip, lap, test, and return a safety valve within 48 to 72 hours during an emergency shutdown.

Common Components That Require Repair

A safety valve fails usually because of wear and tear on its internal moving parts. During a standard overhaul, the following areas receive the most attention:

- The Seating Surfaces: This is where the disc meets the nozzle. Even a microscopic scratch can cause a simmer or leak. Lapping these surfaces to a "light-band" flatness is a core part of the repair.

- The Spring: Over time, springs can lose their rate or suffer from corrosion. If a spring shows signs of pitting or "set," it must be replaced.

- Guide and Stem: Friction here can cause the valve to stick. Cleaning and polishing these parts ensures the safety valve pops at the exact set pressure.

The Step-by-Step Professional Repair Process

The repair of a safety valve is a highly documented and methodical process. It is not just about making it work; it is about proving it will work under pressure.

| Stage | Action Taken | Quality Requirement |

|---|---|---|

| 1. Inspection | Visual check and pre-test (Inlet pressure test) | Identify "as-found" set pressure |

| 2. Disassembly | Sandblasting and parts cleaning | Remove all scale and oxidation |

| 3. Machining | Nozzle and disc lapping | Mirror finish for bubble-tight seal |

| 4. Testing | ASME Section I or VIII test stand | Within +/- 3% of nameplate PSI |

When Is a Safety Valve Non-Repairable?

Despite the high success rate of reconditioning, certain conditions make a safety valve "scrap metal."

Body Erosion and Thinning

If the main casting of the safety valve has been thinned by internal corrosion or erosion to the point where it no longer meets the minimum wall thickness requirements, the valve must be condemned. Welding on the body is generally prohibited by safety codes.

Small Bore Disposables

Small safety valves (usually 1/2" or 3/4" sizes) used for air compressors or small water heaters are often "crimped" or sealed in a way that makes disassembly impossible. For these units, the cost of labor to attempt a repair far exceeds the $50 to $100 cost of a replacement.

The Importance of the "VR" Stamp

You cannot simply hand a safety valve to a local machine shop. To remain compliant with insurance and OSHA regulations, the repair must be done by a shop holding a Certificate of Authorization from the National Board.

Once the safety valve is repaired, a new nameplate (the "VR" tag) is attached, documenting the date, the repair shop, and the verified set pressure. This tag is the only legal proof that the valve is fit for service.

Maintenance Tips to Avoid Frequent Repairs

While a safety valve can be repaired, the goal should be to maximize the time between service intervals.

- Regular Testing: Use the lifting lever (if the system has at least 75% pressure) to ensure the valve isn't stuck.

- Keep the Inlet Clean: Debris is the #1 cause of seat damage. Always flush pipes before installing a newly repaired safety valve.

- Correct Sizing: A valve that "chatters" (opens and closes too fast) will destroy its own seats in minutes. Ensure your safety valve is sized correctly for the flow rate.

English

English русский

русский 中文简体

中文简体