How do you choose a safety valve? Selection tips.

2026-01-12

Content

- 1 Here are some suggestions to consider when choosing a safety valve:

- 1.1 1. What's inside? (Medium Properties)

- 1.2 2. Calculate its "limit" (Set Pressure)

- 1.3 3. Is the "outlet" large enough? (Discharge Capacity)

- 1.4 4. Consider the "resistance" behind it (Back Pressure)

- 1.5 5. Adaptation to the working environment (ambient temperature)

- 1.6 6. Installation location and space

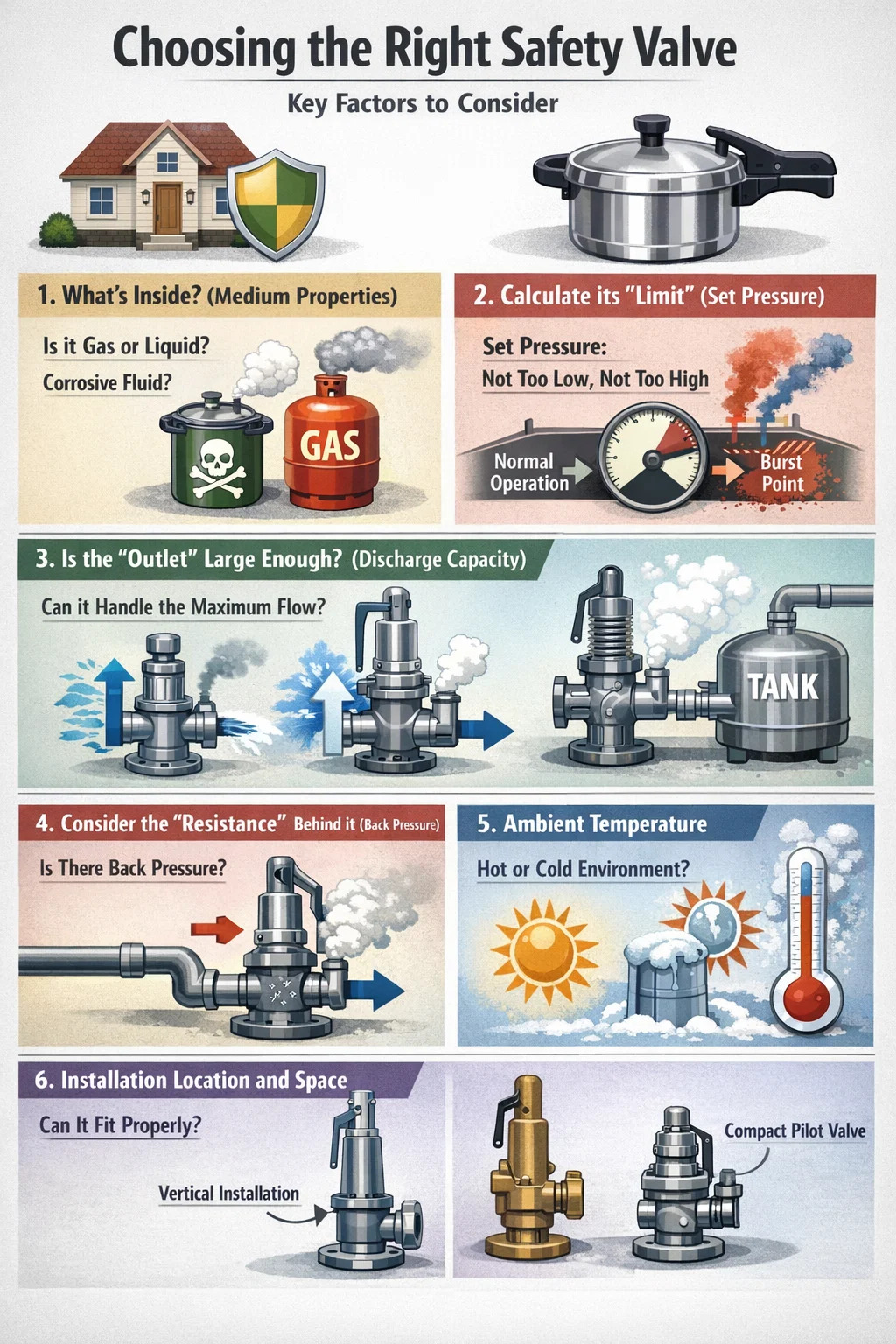

Choosing the right safety valve is like buying insurance for your home or finding the right lid for your pressure cooker – it has to be a perfect match. If you choose the wrong one, it either won't activate when it should, or it will leak continuously.

Here are some suggestions to consider when choosing a safety valve:

1. What's inside? (Medium Properties)

You need to understand what's flowing through the pipe.

Is it gas or liquid? Gases (such as steam, air) and liquids (such as water, oil) have completely different requirements for valves. Gases require valves that can quickly release pressure with a "bang," while liquids require a more stable opening.

Is it corrosive? If the fluid is an acid or alkaline solution, the inner lining and spring of the safety valve must be made of stainless steel or special alloys; otherwise, it will corrode and fail within a few days.

2. Calculate its "limit" (Set Pressure)

This is the most crucial point.

It shouldn't open too early: The opening pressure must be higher than the normal operating pressure of your machine. Otherwise, the valve will continuously spray out fluid as soon as the machine starts, making it impossible to operate.

It absolutely cannot open too late: This value must be lower than the maximum limit your container can withstand. It must be ensured that the safety valve opens and releases the pressure before the tank bursts.

3. Is the "outlet" large enough? (Discharge Capacity)

This is like an escape route; the more people there are, the wider the door needs to be.

You need to estimate how much excess gas or liquid the system will produce per second if the pressure really gets out of control.

The safety valve you choose must have sufficient "capacity," meaning its discharge capacity must be greater than the maximum excess amount the system might produce, so that it can truly reduce the pressure.

4. Consider the "resistance" behind it (Back Pressure)

Sometimes, the fluid discharged by the safety valve is not directly released into the air, but is routed through another pipe.

If this pipe carrying the exhaust is very long, or connected to another pressurized tank, it will create a force pushing back. In this situation, you need to choose a balanced safety valve with a "bellows" to prevent the back pressure from forcing the valve shut and preventing it from opening.

5. Adaptation to the working environment (ambient temperature)

Thermal expansion and contraction: If working in extremely cold or hot environments, the spring stiffness will change. For example, high temperatures will soften the spring, causing the valve to open prematurely before reaching the predetermined pressure.

When selecting, you should inform the manufacturer whether the device will be installed outdoors in direct sunlight or next to a high-temperature furnace.

6. Installation location and space

Some safety valves can only be installed vertically; installing them at an angle may cause them to jam.

If the installation space is very narrow, you may need to choose a smaller pilot-operated valve instead of one with a large lever.

English

English русский

русский 中文简体

中文简体