What are safety valves? (Informational introduction)

2025-12-01

Content

A safety valve is a very important industrial safety device; simply put, it acts like an automatic "pressure relief valve." Here is a point-by-point explanation of safety valves:

1. Core Function: Automatic Pressure Relief Protection

•The main task of a safety valve is to automatically and quickly open when the pressure inside a pipe, container (such as a boiler or pressure vessel), or equipment unexpectedly rises to a dangerous level.

By opening, it allows the excess fluid (gas, steam, or liquid) to be safely released, thus quickly reducing the pressure.

•This is like a "safety floodgate" within the system, preventing unlimited pressure increase.

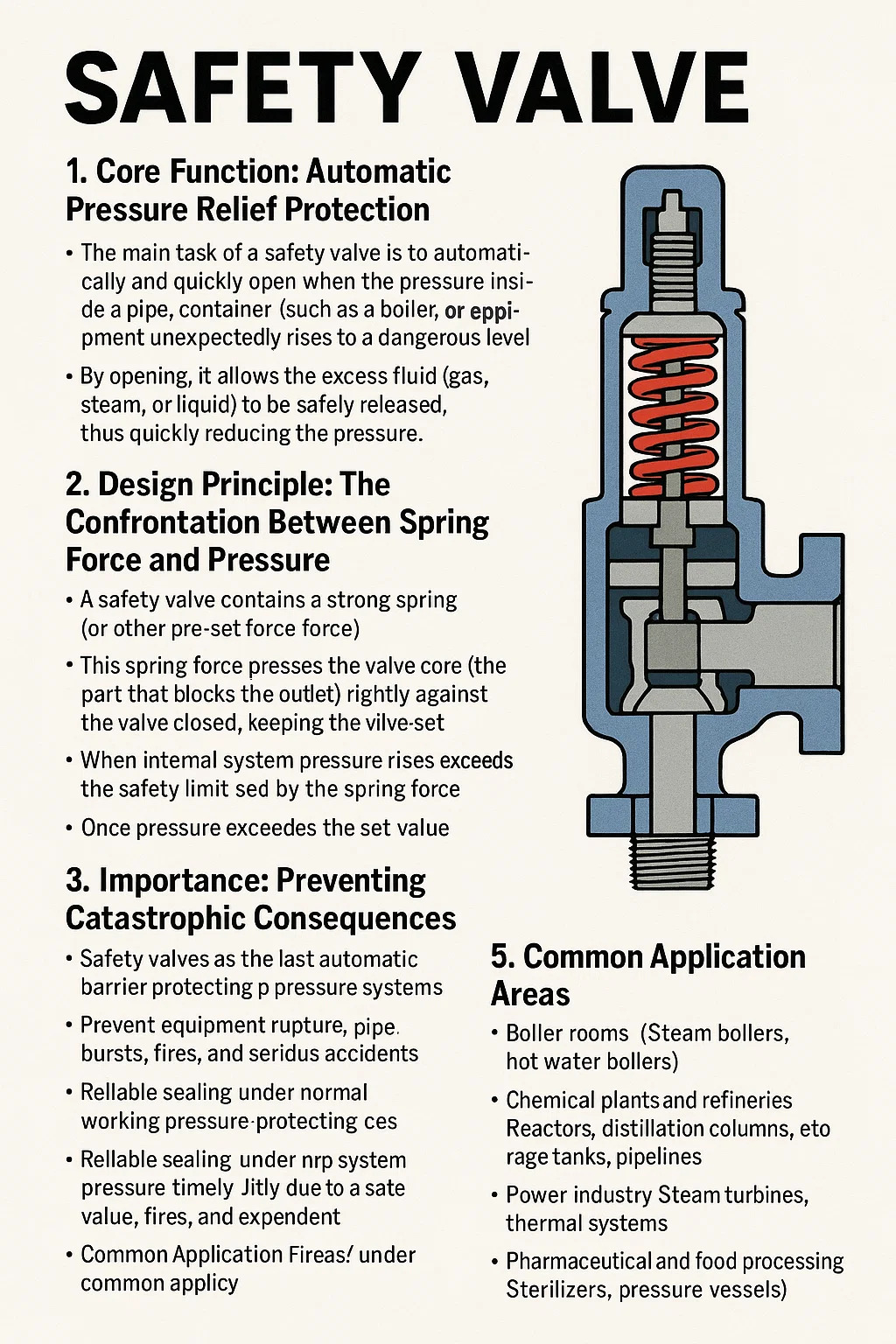

2. Design Principle: The Confrontation Between Spring Force and Pressure

•A safety valve typically contains a strong spring (or other pre-set force).

•This spring force presses the valve core (the part that blocks the outlet) tightly against the valve seat, keeping the valve closed.

•When the internal system pressure rises and exceeds the safety limit set by the spring, the force generated by the internal pressure overcomes the spring force.

•Once the pressure exceeds the set value (which we call the "opening pressure" or "set pressure"), the valve will instantly open and begin to release the pressure.

3. Key Functional Characteristics:

•Automatic Opening: It does not require manual operation or electrical power; it relies entirely on the change in system pressure to trigger the action. This is crucial for its role as the "last line of defense."

•Rapid Full Opening: Once the pressure reaches the critical point, the valve will open to its maximum position as quickly as possible to achieve the fastest pressure relief effect.

•Sufficient Discharge: The discharge port after the valve opens is large enough to ensure that sufficient fluid is discharged when pressure is out of control, effectively reducing the pressure.

•Automatic Closing: When the system pressure drops below a safe value due to the discharge (usually slightly below the opening pressure), the spring force will regain dominance, pushing the valve core closed, and the valve resets. The equipment can then continue to operate safely.

•Reliable Sealing: Under normal working pressure, the valve must be tightly closed without leakage to ensure normal system operation and efficiency.

4. Importance: Preventing Catastrophic Consequences

•Safety valves are the last automatic barrier protecting the safety of pressure systems. If a pressure vessel (such as a boiler, reactor, or compressed air storage tank) is overpressurized without a safety valve or if the safety valve fails, the consequences can be extremely serious. By releasing pressure in a timely manner, it can effectively prevent equipment rupture, pipe bursts, fires, and even more serious accidents, protecting personal safety, equipment, property, and the environment.

5. Common Application Areas:

•Safety valves are widely used in various industrial and civil fields involving pressure operations, such as:

•Boiler rooms: Steam boilers, hot water boilers.

•Chemical plants and refineries: Reactors, distillation columns, storage tanks, pipelines.

•Power industry: Steam turbines, thermal systems.

•Pharmaceutical and food processing: Sterilizers, pressure vessels.

•Compressed air systems: Air storage tanks.

•HVAC systems: Chillers, heat exchangers.

•Oil and gas industry: Extraction, transportation, and storage equipment.

English

English русский

русский 中文简体

中文简体