What are the different types of safety valves?

2025-12-15

Content

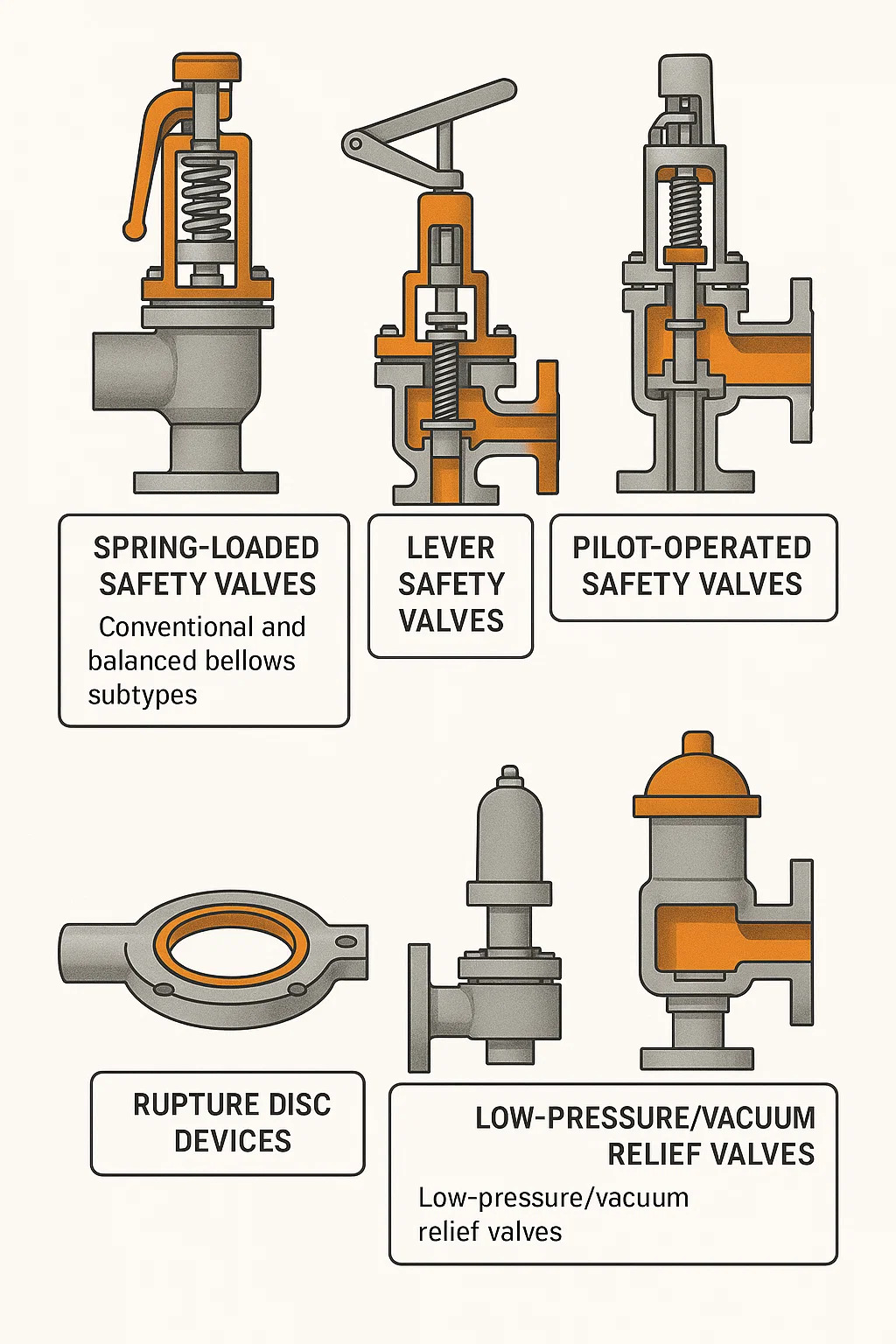

Safety valves are critical devices for protecting pressure equipment. They automatically open when the pressure exceeds a preset limit, releasing the medium (such as gas or liquid), thus preventing equipment damage or hazards. Based on their operating method and structural characteristics, the main types are:

1. Spring-Loaded Safety Valves

This is the most common and basic type, using the force of a spring to counteract the internal pressure of the system.

Working Principle: Under normal operating pressure, the spring presses the valve disc tightly against the valve seat, maintaining a seal. When the system pressure rises above the spring's set force, the valve disc is lifted, and the medium begins to discharge.

Features: Relatively simple structure and high reliability.

Subtypes:

Conventional: Discharge back pressure directly affects the set opening pressure.

Balanced Bellows: Uses a bellows to counteract the effect of back pressure on the valve opening pressure, ensuring accurate opening even under varying back pressure.

2. Lever Safety Valves

This type of safety valve uses a combination of a lever and a counterweight to provide the closing force.

Working Principle: A lever is connected to the valve disc, and a movable counterweight is suspended from the other end of the lever. By adjusting the position of the counterweight on the lever, the valve's opening pressure can be precisely set.

Features: Relatively bulky structure, often used in large equipment such as steam boilers, facilitating manual lifting of the valve for regular drainage (called "manual blowdown" or "manual venting"). Less widely used in modern industry than spring-loaded types.

3. Pilot-Operated Safety Valves

This type uses the system pressure itself to control the opening and closing of the valve, consisting of a main valve and a small control device (pilot valve).

Working Principle: The pilot valve first senses the system pressure. When the pressure reaches the set value, the pilot valve opens, releasing the pressure at the top of the main valve, allowing the system pressure to push the main valve open and perform a large-scale discharge.

Features:

More precise opening: The pressure can be very close to the set point before opening.

Large discharge volume: The main valve can be made very large.

Suitable for high-pressure systems: Compared to spring valves, they can be designed to be more compact while handling large flow rates.

4. Rupture Disc Devices

Strictly speaking, this is not a traditional valve, but rather a single-use pressure relief device.

Working Principle: It consists of a pre-calibrated thin metal membrane (or non-metallic material) installed on a container. When the container pressure reaches a specific value, the membrane ruptures instantly, rapidly releasing the pressure.

Features:

Extremely fast response speed.

Single-use: Must be replaced after rupture.

Can be used in combination with safety valves: The rupture disc is located on the inlet side of the safety valve to protect the safety valve from corrosion or prevent minor leaks.

5. Low-Pressure/Vacuum Relief Valves

These safety valves are specifically designed to protect large containers such as storage tanks from deformation or damage due to excessive pressure or **vacuum (extremely low internal pressure)**.

Working Principle:

Pressure Relief: When the internal pressure exceeds the set value, the valve opens to release the internal gas.

Vacuum Relief: When the internal pressure falls below atmospheric pressure (creating a vacuum), the valve opens to draw in external air, balancing the internal and external pressures.

Features: Protects the structural integrity of the storage tank and is typically used in low-pressure environments.

English

English русский

русский 中文简体

中文简体