What happens if a safety valve fails? (Warning signal)

2025-12-29

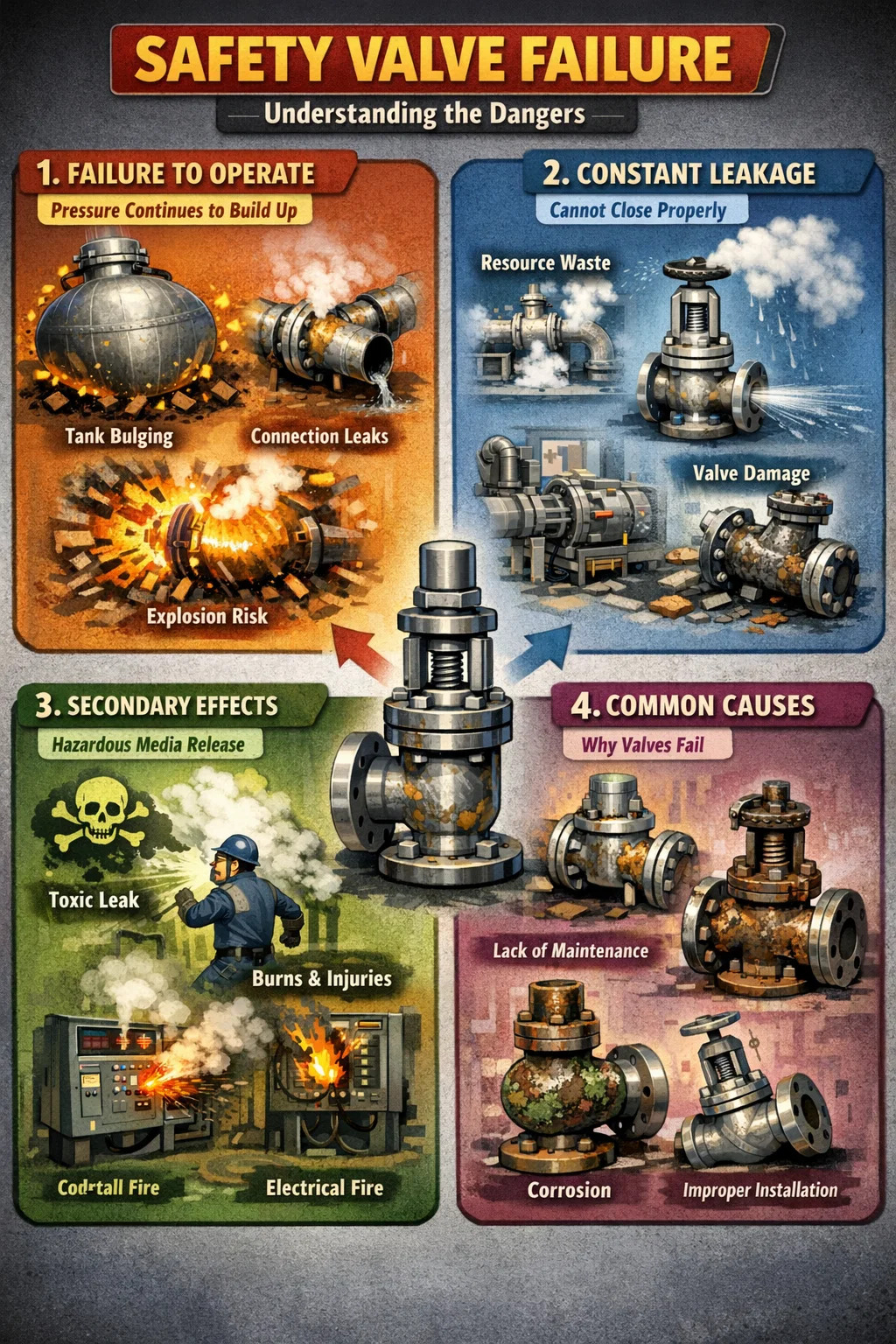

If a **safety valve** fails, the consequences usually fall into two completely different categories depending on "how" it fails. You can imagine it like the pressure release valve on a pressure cooker; if this valve is blocked or constantly leaking, the situation inside the pot will become very dangerous.

Here are some possible scenarios that can occur after a safety valve failure:

1. Failure to operate: Pressure continues to build up (the most dangerous situation)

If the safety valve fails to open in time due to rust, blockage by impurities, or a stuck spring, the system loses its last line of defense.

Equipment deformation: Like an overinflated balloon, the metal tank or pipes will begin to expand and bulge due to the unbearable internal pressure.

Leakage at connections: Since the predetermined outlet cannot open, the pressure will seek out the weakest point to escape, such as flange connections, seals, or welds, resulting in a large amount of media being released.

Structural damage: In severe cases, the pressure will directly rupture the equipment, causing the entire container to be torn apart like cardboard, resulting in massive physical damage to the surrounding environment.

2. Frequent opening or constant leakage: Cannot close properly

Another situation is that the safety valve is too "sensitive," or the valve core does not close properly, causing it to constantly release pressure.

Resource waste: The valve constantly leaking gas or liquid means that energy (such as steam) or materials in the system are being wasted, which directly increases operating costs.

System shutdown: Because of the constant "leakage," the system cannot build up enough pressure, preventing the machine from working properly, and the entire production line may shut down as a result.

Valve damage: The valve frequently opening and closing (professionally called "chattering") will constantly impact the valve seat like hammering nails, quickly damaging the parts and rendering them completely unusable.

3. Secondary effects caused by media leakage

When a safety valve failure leads to the uncontrolled release of media (such as chemical gases or high-temperature steam), it can trigger a series of chain reactions:

Environmental pollution: If the contents are odorous or environmentally harmful gases, once released, the surrounding air and soil will be affected. Risk of burns or poisoning: High-temperature steam or chemical substances, if sprayed onto areas where operators frequently walk, can pose a significant safety hazard.

Electrical faults: If the sprayed liquid or steam wets nearby control cabinets or wires, it may cause short circuits, leading to fires or other electrical damage.

4. Why do they fail? (Common causes)

Lack of maintenance: Just like a car needs maintenance, if a safety valve is not tested regularly (by pulling the handle to release pressure), the internal parts can easily rust together.

Incorrect selection: Installing a valve that is not suitable for the medium, such as using ordinary steel to handle highly corrosive liquids, will cause the valve to corrode quickly.

Improper installation: If the valve is installed crookedly, the internal components will be subjected to uneven stress, which can also cause it to malfunction at a critical moment.

English

English русский

русский 中文简体

中文简体