Is a pressure relief valve a safety valve?

2026-01-19

Content

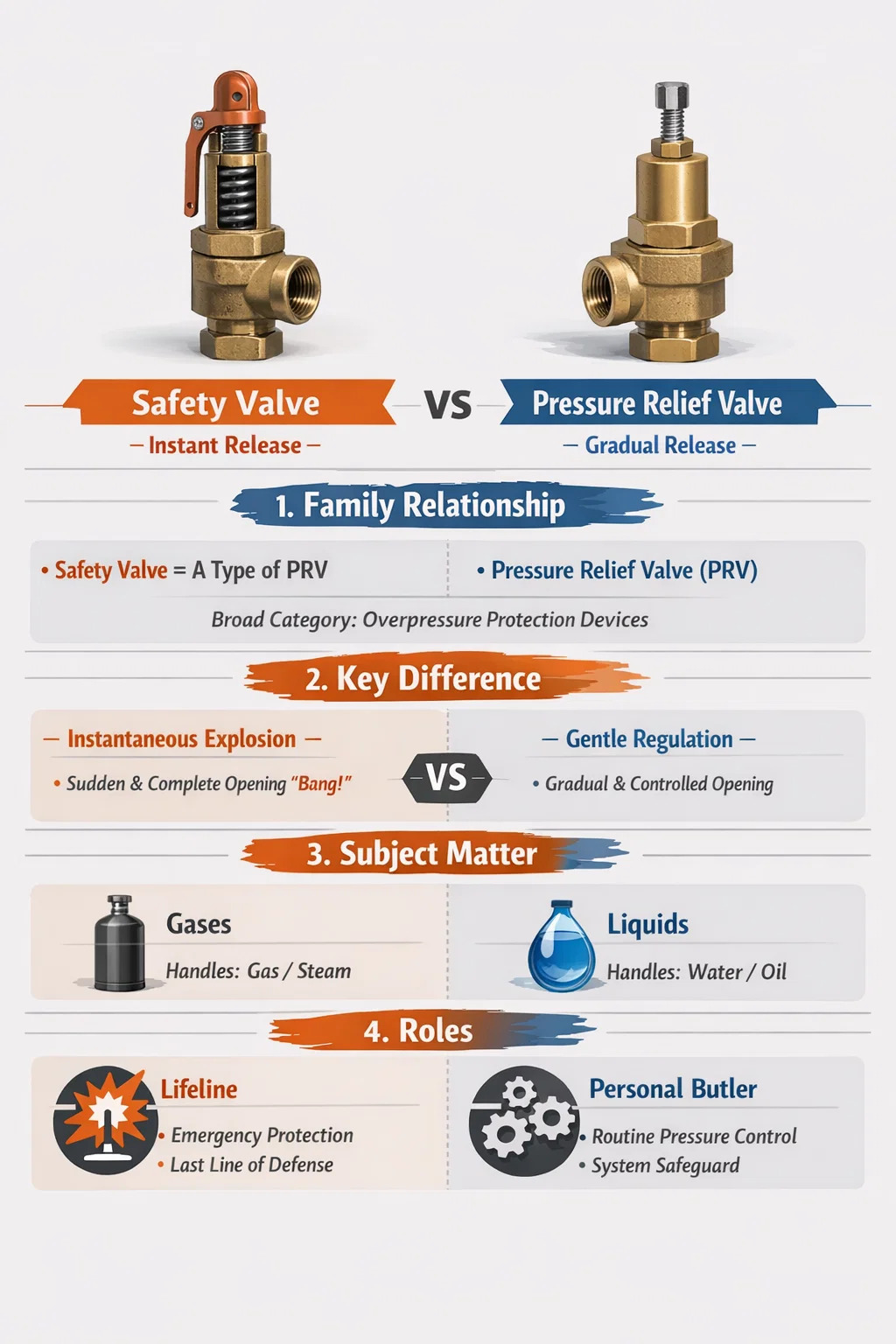

Pressure relief valves (PRVs) and safety valves are closely related. In the broad industrial classification, they both belong to "overpressure protection devices," but in practical applications and characteristics, they are not entirely the same.

1. Family Relationship: Inclusion and Being Inclusion

Technically, "pressure relief valve" is actually a broad term.

A safety valve is a type of pressure relief valve: In many international standards, safety valves are considered a specific member of the pressure relief valve family.

Common Name: On many construction sites, foremen may feel it's unnecessary to distinguish so precisely and casually call safety valves also pressure relief valves, which is not incorrect in common communication.

2. Key Difference: Instantaneous Explosion vs. Gentle Regulation

Although they both "release air" or "drain water," their operating styles are completely different:

A safety valve prioritizes speed: As soon as the pressure exceeds the limit, it will instantly and completely "jump open," accompanied by a loud bang. It doesn't aim for precise adjustment, but rather to completely reduce pressure within a second before danger occurs.

A pressure relief valve (PRV) prioritizes "precision": it's more like a regulator. If the pressure is slightly too high, it opens a small gap; if the pressure is even higher, it opens wider. It maintains the system pressure at a stable level through this gentle approach, rather than violently releasing pressure like a safety valve.

3. Subject Matter: Gas vs. Liquid

This is the simplest way to distinguish them:

Safety valves typically handle "gas": Because gases are compressible, uncontrolled pressure is extremely dangerous, like a compressed spring, hence the need for the explosive protection of a safety valve.

Pressure relief valves typically handle "liquid": Liquids (such as water or hydraulic oil) are almost incompressible. When handling liquid systems, there's no need for a violent evacuation like a gas tank; releasing just a small amount of liquid will immediately reduce the pressure, making a gently regulating pressure relief valve suitable.

4. Roles: Lifeline vs. Personal Butler

A safety valve is the "last line of defense": It's designed to prevent serious equipment damage. It won't activate unless absolutely necessary. Once it activates, it usually means there's a major problem with the system.

A pressure relief valve is for "routine patrols": It's primarily for protecting pressure-sensitive precision instruments. During machine operation, it may frequently open slightly to help the system release excess pressure fluctuations.

English

English русский

русский 中文简体

中文简体