Automotive Brake Valve Seat Industry Knowledge

I. Automotive Brake Valve Seat Product Knowledge

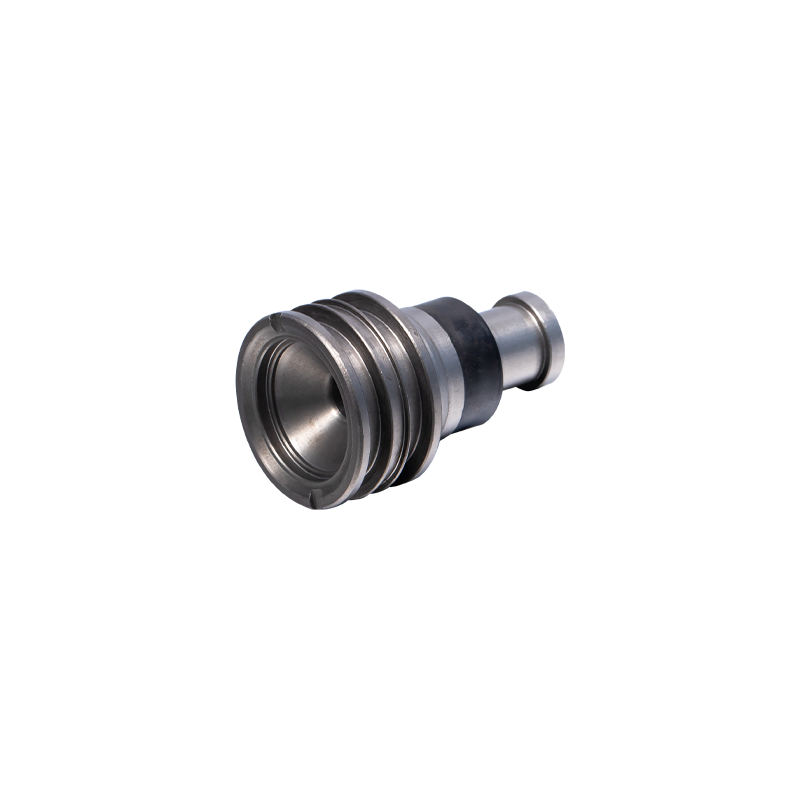

(I) Working Principle

The automotive brake valve seat is a critical component in the braking system, and its operating principle is closely linked to the overall operation of the brake valve. When the driver depresses the brake pedal, the brake valve's pull arm is pulled, and the upper seat of the balancing spring is pressed downward under pressure. This movement, through the coordinated action of the balancing spring and the lower seat, pushes the steel ball, which in turn moves the push rod downward. The downward movement of the push rod moves the two-chamber diaphragm assembly, eliminating the gap in the process. Subsequently, the exhaust valve port closes first, followed by the intake valve port. At this point, compressed air in the air reservoir flows through the channel and into the brake chamber. The powerful air pressure pushes the adjusting arm, causing the cam to rotate, ultimately pressing the brake shoe firmly against the brake drum, achieving braking effect. The brake valve seat acts as a precise "gatekeeper" in this process, ensuring the seal between the various components of the brake valve, preventing compressed air leakage, and maintaining stable pressure in the brake system, thereby ensuring efficient and stable braking. For example, in the braking systems of some heavy trucks, the excellent sealing performance of the brake valve seat ensures stable brake pressure even under frequent braking operations, ensuring driving safety.

(II) Product Classification

Brake valve seats can be broadly categorized into metal and non-metallic materials. Common metal brake valve seats include cast iron and aluminum alloy. Cast iron valve seats offer high strength and wear resistance, making them suitable for commercial vehicle brake systems with high braking performance requirements and harsh operating environments, such as large trucks and buses. Aluminum alloy valve seats, due to their light weight and excellent heat dissipation, are increasingly used in lightweight passenger vehicles, particularly new energy vehicles, helping to reduce vehicle weight and increase range. Non-metallic brake valve seats, such as rubber and plastic composites, offer excellent sealing and corrosion resistance and are commonly used in brake systems with extremely stringent sealing requirements. They effectively prevent brake fluid leakage and ensure proper operation of the brake system. Brake valve seats can be categorized into integral and split types. Integral valve seats have a simple structure, are easy to install, and ensure high sealing performance. However, if the valve seat is damaged during repair or replacement, the entire valve seat may need to be replaced. Split valve seats, on the other hand, consist of multiple components. During repair, specific components can be replaced based on the specific damage, reducing repair costs. However, this requires higher installation precision.

(III) Materials and Processing

Material Selection:

Metallic materials: Cast iron, as mentioned above, has a high carbon content and excellent casting properties, allowing it to be cast into complex shapes to meet the diverse structural design requirements of brake valve seats. Furthermore, cast iron's hardness and wear resistance ensure it remains in good working condition even under frequent brake pressure shocks, resulting in a long service life. Aluminum alloys, with their low density and high strength, are highly favored in the trend toward lightweighting in automobiles. Alloying elements in aluminum alloys, such as silicon and magnesium, further enhance their mechanical properties, ensuring brake valve seat strength while effectively reducing weight.

Non-metallic materials: Rubber materials offer excellent elasticity and flexibility, allowing them to fit tightly against other brake valve components, creating a good seal. During braking, it can adapt to minor displacements and deformations between components, maintaining a consistent seal. Plastic materials offer excellent corrosion resistance and insulation properties. When combined with rubber, they combine the advantages of both to enhance the performance of brake valve seats. For example, some valve seats made from a rubber-PTFE composite combine the elastic sealing properties of rubber with the high chemical stability and low friction coefficient of PTFE, effectively reducing energy loss during braking.

Manufacturing Process:

Casting: Casting is a common manufacturing process for metal brake valve seats. Sand casting is a cost-effective method suitable for producing valve seats with complex shapes and large production runs. A sand mold is created, into which molten metal is poured. After cooling, the desired valve seat blank is obtained. Subsequent machining processes, such as turning and grinding, are then performed to achieve precise dimensional and surface finish requirements.

Injection Molding: Injection molding is widely used in the manufacture of non-metallic brake valve seats. Plastic pellets are heated and melted, then injected into the mold cavity. After a period of pressure maintenance and cooling, the plastic is formed into the shape of the valve seat. This process enables high-precision and high-efficiency production, and various additives, such as reinforcements and flame retardants, can be added during the injection molding process to improve the properties of the plastic.

Surface treatment: To further enhance the performance and service life of brake valve seats, surface treatment is often required. For metal valve seats, common surface treatment processes include electroplating and thermal spraying. Electroplating creates a uniform metal coating, such as chrome plating or zinc plating, on the valve seat surface, improving its corrosion and wear resistance. Thermal spraying heats a material, such as metal or ceramic, to a molten state and then sprays it onto the valve seat surface using a spray gun, creating a coating with specialized properties, such as increased hardness and thermal insulation. For non-metallic valve seats, surface treatment primarily involves surface modification, such as plasma treatment, to improve surface adhesion and sealing.

II. Yuyao Zhedong Automotive Parts Factory Co., Ltd. Information

(I) Production Capacity

Yuyao Zhedong Automotive Parts Factory Co., Ltd., established in September 1988, is located in the Yuyao Economic Development Zone, Zhejiang Province, and covers an area of over 3,500 square meters. The company boasts a comprehensive production facility layout encompassing a hardware workshop, a rubber workshop, an adhesive workshop, and a mold manufacturing center. The hardware workshop is equipped with advanced metalworking equipment, enabling precise cutting, forming, and processing of metal raw materials, ensuring the production of high-quality metal brake valve seats. The rubber workshop specializes in the production of rubber products, equipped with specialized rubber mixing and molding equipment. It can produce a variety of high-performance rubber seals for brake valve seat sealing applications, tailored to specific product requirements. The adhesive workshop is equipped with advanced adhesive mixing and coating equipment, enabling precise application of adhesive to brake valve seat components, ensuring a secure connection and a good seal. The mold manufacturing center is one of the company's core technologies, boasting an experienced mold design and manufacturing team, as well as high-precision mold processing equipment, such as CNC machining centers. This enables the company to quickly design and manufacture high-quality molds tailored to individual customer needs, providing strong support for brake valve seat production. Leveraging these comprehensive production facilities and a dedicated team, the company currently boasts an annual production capacity exceeding 5 million brake valve seats, establishing a leading position in the domestic brake valve seat manufacturing industry.

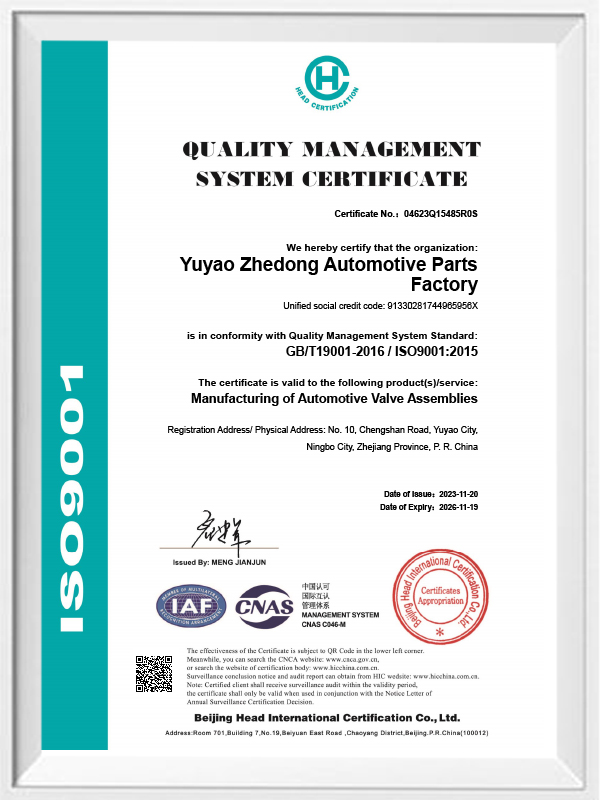

(II) Quality Control

Since its founding, the company has consistently adhered to the principle of "serving customers with sincerity" and has considered product quality its lifeline. Within its internal quality management, a rigorous quality control system has been established. Starting with raw material procurement, suppliers are rigorously screened and evaluated to ensure that metals, rubber, and other raw materials meet high-quality standards. Throughout the production process, rigorous quality control points are implemented at every step, using advanced testing equipment and professional quality inspectors to conduct real-time product testing and monitoring. For example, during the brake valve seat processing, high-precision measuring instruments are used to verify dimensional accuracy to ensure compliance with design requirements. In the production of rubber seals, we utilize specialized sealing performance testing equipment to rigorously test their sealing performance. Before shipment, we also conduct comprehensive quality inspections, comprehensively testing all performance indicators of brake valve seats. Only products that pass all these tests are allowed to be released. Furthermore, the company successfully obtained GB/T19001-2000idt and ISO9001:2000 international quality system certifications in the early 21st century. This not only represents a high degree of recognition for our quality management system, but also further motivates us to continuously improve our quality management, enhance product quality stability, and provide customers with more reliable products.

(III) Market and Customers

The company's products are primarily targeted at automotive brake system manufacturers, serving a broad and high-quality customer base. Currently, the company supplies automotive brake valve seats to numerous well-known companies, including China First Automobile Group, China Second Automobile Group, Wanxiang Group, Zhejiang Keli, Zhejiang Dehan, Zhejiang Angu, Zhejiang Hengli, and Zhuji Gongzheng. Through long-term collaboration with these customers, the company has earned their trust and recognition through its stable product quality, strong supply capacity, and excellent after-sales service. In the domestic market, the company's products are widely used in the brake valve seat field for both commercial vehicles and passenger cars, occupying a significant market share. In particular, in the commercial vehicle brake valve seat market, the company, relying on the high reliability and durability of its products, has established long-term and stable cooperative relationships with many commercial vehicle OEMs, becoming one of their key parts suppliers. Although the company has not yet disclosed its overseas market expansion, with the continuous improvement in the competitiveness of China's automotive parts industry in the international market and the industrial advantages of Yuyao City as a hub for the automotive parts industry, the company is expected to further expand its overseas market in the future, bringing high-quality automotive brake valve seat products to the international market and enhancing the company's international influence.

English

English русский

русский 中文简体

中文简体

02 Feb 2026

02 Feb 2026