Aluminum Alloy/Copper Machined Parts Industry Knowledge

What are the unique material properties of aluminum alloy/copper machined parts?

Aluminum alloy parts are highly sought after in the industrial sector for their lightweight and high strength. With a density typically around 2.7g/cm³, only about one-third that of copper, they can effectively reduce the overall weight of a product while also offering excellent corrosion resistance and thermal conductivity. Copper parts, on the other hand, are renowned for their excellent electrical and thermal conductivity, reaching over 90% and far exceeding most metals. They also possess excellent ductility and wear resistance, making them suitable for parts requiring precision conduction or wear resistance.

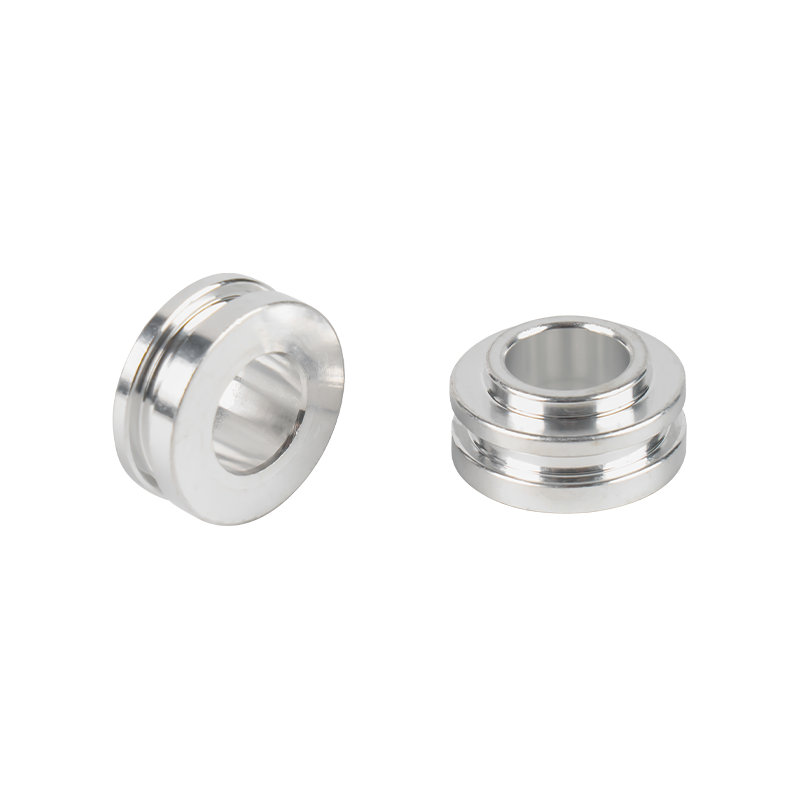

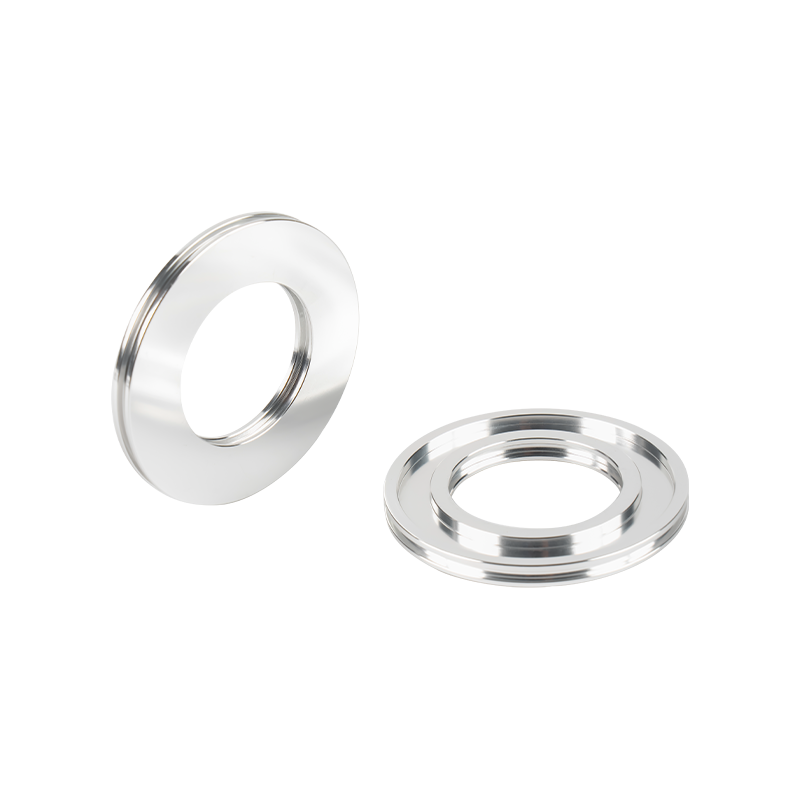

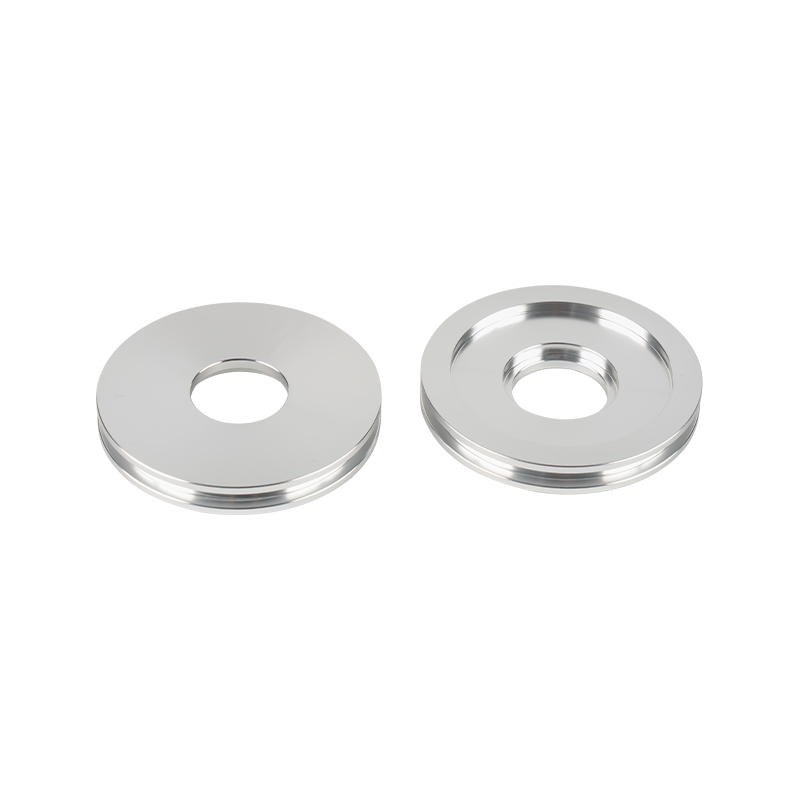

Yuyao Zhedong Automotive Parts Factory Co., Ltd. manufactures a series of automotive brake valve seats. They carefully select materials such as aluminum alloy or copper based on the functional requirements of each component. Leveraging a deep understanding of material properties, they ensure stable performance within the automotive brake system.

What are the common machining processes for aluminum alloy/copper machined parts?

A wide variety of machining processes are available for aluminum alloy/copper machined parts, including turning, milling, drilling, and grinding. Turning can be used to machine rotating parts, ensuring cylindricity and circular runout; milling can produce complex shapes such as flat surfaces and grooves; drilling is used to create holes of various diameters; and grinding can improve the surface and dimensional accuracy of parts.

Yuyao Zhedong Automotive Parts Factory Co., Ltd. boasts a hardware workshop, a rubber workshop, an adhesive workshop, and a mold manufacturing center. Equipped with advanced processing equipment and professional technicians, they expertly utilize various processing techniques to ensure that products such as automotive brake valve seats meet high-precision requirements.

What are the applications of aluminum alloy/copper machined parts?

Aluminum alloy parts, due to their lightweight properties, are widely used in automotive manufacturing, aerospace, and rail transportation, such as engine components and body frames. Copper parts, due to their excellent electrical and thermal conductivity, are particularly useful in electronics, refrigeration equipment, and hydraulic systems, such as connectors for appliances and condensers for refrigeration equipment. Yuyao Zhedong Automotive Parts Factory Co., Ltd. primarily produces a series of automotive brake valve seats, a specific application of aluminum alloy/copper machined parts in the automotive industry. These products are supplied to renowned companies such as China First Automobile Group and China Second Automobile Group, fully demonstrating the importance of these parts in the automotive industry.

How can the quality of aluminum alloy/copper machined parts be ensured?

Ensuring the quality of aluminum alloy/copper machined parts requires multi-faceted control. First, raw materials must be rigorously screened to ensure that their performance meets the required standards. Second, during the machining process, machining parameters such as cutting speed and feed rate must be precisely controlled to avoid inappropriate parameters affecting part quality. Third, comprehensive quality testing is performed, including dimensional accuracy, surface roughness, and mechanical properties.

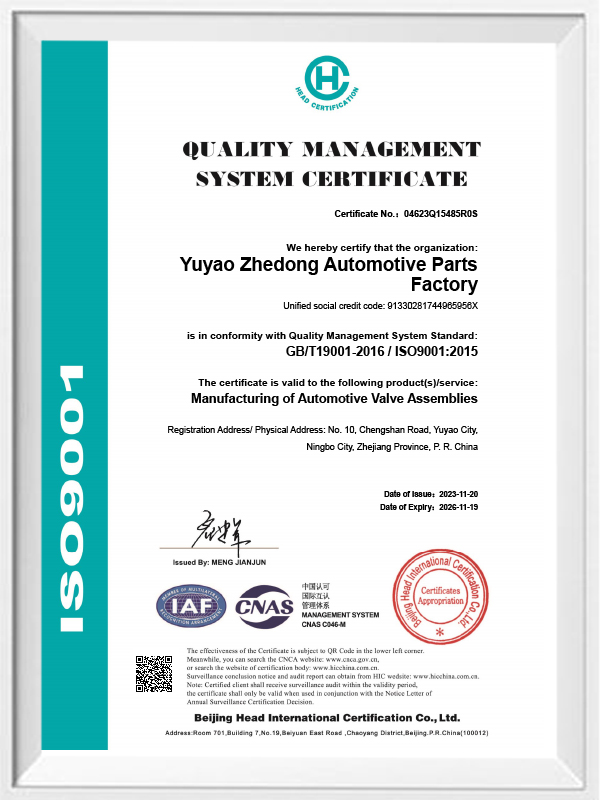

Since its establishment, Yuyao Zhedong Automotive Parts Factory Co., Ltd. has consistently prioritized product quality, focusing internally on comprehensive quality and externally on fostering its product image. At the beginning of the new century, we obtained GB/T19001-2000IDT and ISO9001:2000 international quality system certifications. Through a comprehensive quality control system, we have further stabilized product quality.

What factors influence the production capacity of aluminum alloy/copper machined parts?

The production capacity of aluminum alloy/copper machined parts is influenced by factors such as the level of equipment advancement, the technical level of workers, and the efficiency of production management. Advanced processing equipment improves processing efficiency and precision; skilled workers can better operate the equipment and reduce production errors; and scientific production management can rationalize production plans, optimize production processes, and improve production efficiency.

Yuyao Zhedong Automotive Parts Factory Co., Ltd. currently occupies over 3,500 square meters and has multiple specialized workshops and a mold manufacturing center. It has an annual production capacity of over 5 million valve seats, thanks to its continuous improvement of equipment, training of professional personnel, and optimized production management.

English

English русский

русский 中文简体

中文简体

02 Feb 2026

02 Feb 2026