Rubber Parts Industry Knowledge

What are the performance differences between natural rubber and synthetic rubber in rubber parts?

Natural rubber is processed from the sap of rubber trees and has excellent elasticity, tensile strength, abrasion resistance, and tear resistance. It is suitable for parts subjected to repeated friction and pressure, such as tires and hoses.

Synthetic rubber is produced through chemical synthesis, and different types have different properties: Nitrile rubber offers excellent oil and chemical resistance and is commonly used in seals and oil hoses; silicone rubber is stable in high and low temperature environments and is non-toxic, making it suitable for parts in the medical and food industries; fluororubber is extremely chemically stable and can be used in high-temperature and highly corrosive environments; EPDM rubber offers excellent weather and chemical resistance and is often used in building waterproofing, automotive weather stripping, and other fields.

What steps are involved in the rubber parts production process?

The rubber parts production process mainly includes the following steps:

1. Plastication: Mechanical action degrades the long-chain molecules of the raw rubber, increasing its plasticity and paving the way for subsequent processing. 2. Mixing: The plasticized raw rubber is thoroughly mixed with the vulcanizer, accelerator, filler, and other compounding agents to meet the specific product performance requirements.

3. Molding: Depending on the product shape and precision requirements, injection molding (suitable for parts with complex structures and high dimensional accuracy), compression molding (suitable for parts with regular shapes and large batches), and extrusion molding (suitable for continuous production of products with consistent cross-sectional shapes, such as hoses and sealing strips) can be used.

4. Vulcanization: Heating and other methods are used to induce cross-linking reactions in the rubber molecules, transforming the rubber from a plastic state to an elastomer, significantly improving its physical and mechanical properties.

Yuyao Zhedong Automotive Parts Factory Co., Ltd. has a professional rubber workshop. During the production process, strict control is exercised over raw material selection, temperature and time control during plasticizing and mixing, and mold and process parameter management during the molding and vulcanization stages to ensure product quality.

What are the performance requirements for rubber parts in different industries?

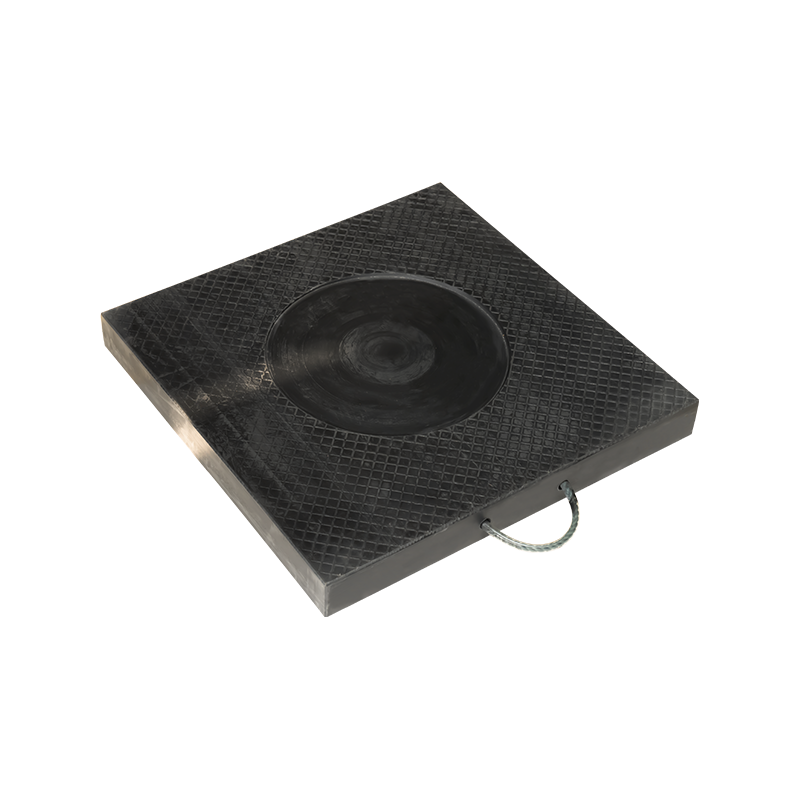

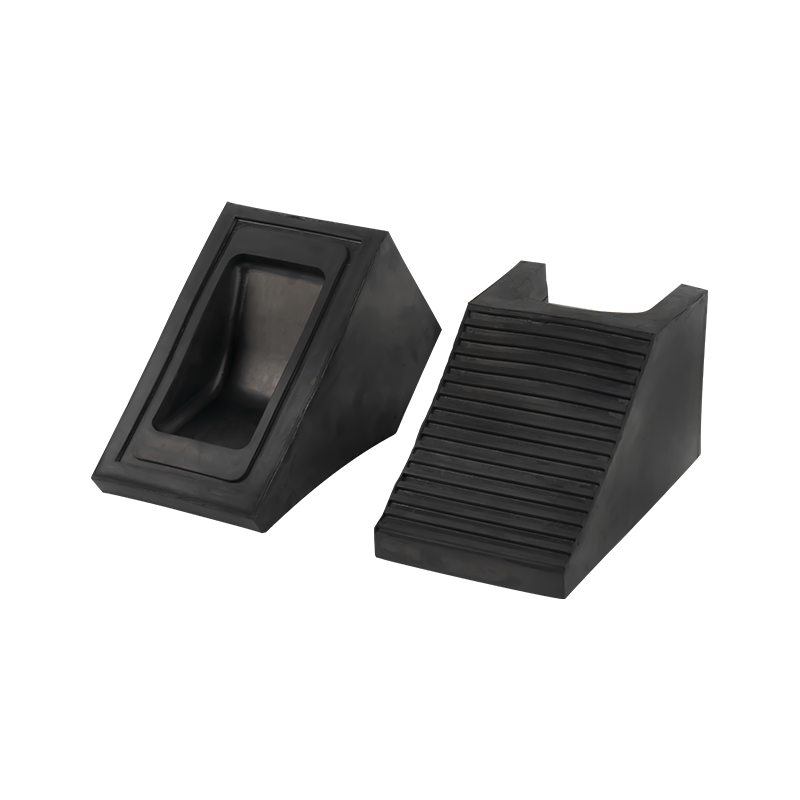

1. Automotive Industry: Tires must possess excellent wear resistance, grip, and aging resistance; seals must offer excellent sealing performance, effectively preventing leaks and providing sound insulation; shock absorbers must provide excellent shock absorption; and rubber parts for braking systems must ensure sensitive and reliable braking. Yuyao Zhedong Automotive Parts Factory Co., Ltd. produces automotive brake valve seats and other parts for companies such as China First Automobile Group and China Second Automobile Group, meeting these performance requirements.

2. Industrial Sector: Rubber hoses must be pressure-resistant and corrosion-resistant to ensure stable gas and liquid transport; seals must offer reliable sealing to prevent leakage; and conveyor belts must be strong and wear-resistant to meet material transport needs.

3. Medical Industry: Medical gloves must be flexible, have a strong seal, and be biocompatible; infusion tubing must be chemically stable and non-toxic; and rubber stoppers must provide excellent sealing to prevent moisture and contamination of pharmaceuticals.

4. Construction Industry: Sealing strips must be waterproof, dustproof, and soundproof to improve building energy efficiency and comfort; shock absorbers must reduce vibration and impact to enhance structural stability.

What aspects does the quality control system for rubber parts include?

1. Raw Material Quality Control: We rigorously select suppliers and test each batch of raw rubber for purity, Mooney viscosity, tensile strength, and other indicators, as well as the chemical composition, particle size, and activity of compounding agents, to ensure that raw materials meet quality standards.

2. Production Process Monitoring: We precisely control process parameters such as temperature, pressure, time, and speed during plasticating, mixing, molding, and vulcanization. Automated control systems and sensors monitor these parameters in real time, allowing for timely adjustments to deviations. We also regularly perform equipment maintenance to ensure proper operation.

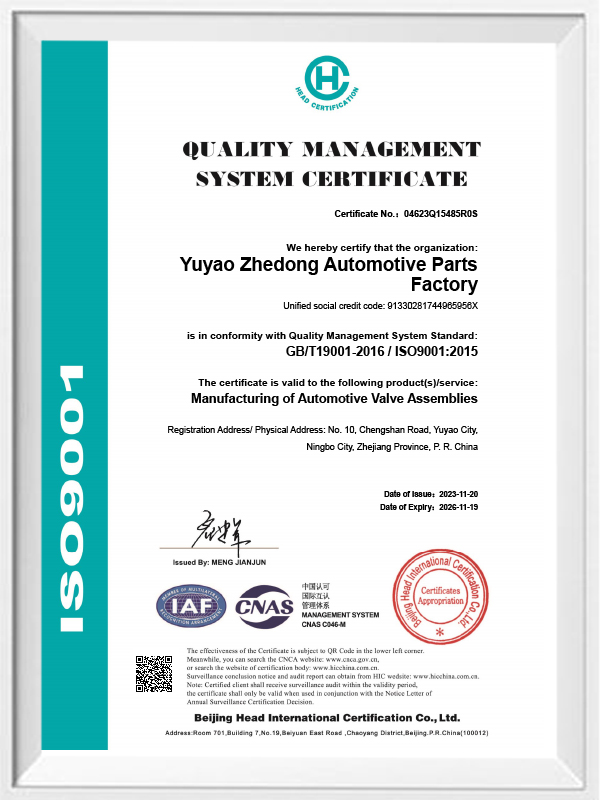

3. Finished Product Quality Testing: We have established a professional quality testing laboratory equipped with advanced testing equipment to test rubber parts for appearance (checking for defects such as bubbles, cracks, and missing rubber), dimensions (ensuring compliance with design requirements), physical properties (testing tensile strength, hardness, tear strength, compression set, etc.), and chemical properties (analyzing oil resistance, chemical resistance, and aging resistance). Yuyao Zhedong Automotive Parts Factory Co., Ltd. adheres to the principle of "Sincere Customer Service" and has obtained GB/T19001-2000IDT and ISO9001:2000 international quality system certifications. Strict testing is implemented throughout the entire process, from raw materials entering the factory to finished products leaving the factory, to ensure consistent product quality.

What are the development trends of rubber parts?

1. High-Performance Material R&D: Focusing on developing rubber materials with higher strength, temperature resistance, corrosion resistance, wear resistance, and low rolling resistance, improving the overall performance of rubber through molecular design and material compounding technologies.

2. Green and Environmentally Friendly Production: Utilizing environmentally friendly raw materials and production processes to reduce pollutant emissions, such as promoting water-based adhesives instead of solvent-based adhesives; and developing biodegradable rubber materials to reduce the impact of waste on the environment.

3. Intelligent Manufacturing: Introducing automated equipment, robotics, and information management systems to achieve intelligent control and management of the production process, improving production efficiency, reducing costs, and enhancing product quality consistency. 4. Customized Services: Based on individual customer needs, we provide one-stop solutions from material selection and process design to product manufacturing, meeting the performance requirements of diverse application scenarios.

Yuyao Zhedong Automotive Parts Factory Co., Ltd. is aligning with industry trends and increasing R&D investment to explore the application of high-performance rubber materials in its products. We are optimizing production processes and moving toward green, environmentally friendly, and intelligent manufacturing to enhance our market competitiveness.

English

English русский

русский 中文简体

中文简体

02 Feb 2026

02 Feb 2026