Pneumatic Brake Valve: The Core of Commercial Vehicle Safety

In the braking systems of commercial vehicles, such as heavy trucks and buses, pneumatic brake valves play a crucial role. Unlike the hydraulic brakes commonly used in passenger cars, commercial vehicles, due to their heavy loads and high inertia, generally utilize pneumatic brake systems. This system utilizes compressed air as the power transmission medium, and the pneumatic brake valve is the "command center" of this system.

Core Functions:

The pneumatic brake valve's primary function is to precisely control the flow and pressure of compressed air from the air reservoir to the brake chamber. It responds to the driver's brake pedal input (depressing or releasing the brake pedal), and through the coordinated operation of its precise internal components, including the valve core and valve seat, it achieves:

1. Braking Response: Rapidly and smoothly builds up brake pressure.

2. Pressure Regulation: Linearly adjusts the output air pressure based on pedal travel and force, achieving varying degrees of braking force.

3. Brake Release: Rapidly releases the air pressure within the brake chamber to ensure timely release of the wheels. 4. Safety Redundancy: Some advanced valve body designs include fail-safe features, ensuring they can still provide basic braking force even if a partial circuit fails.

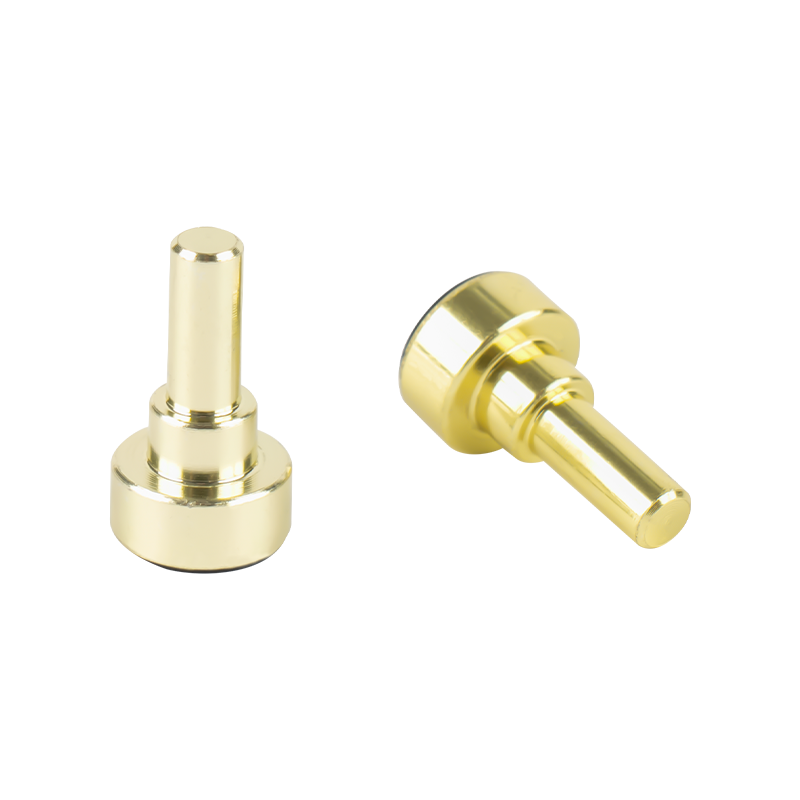

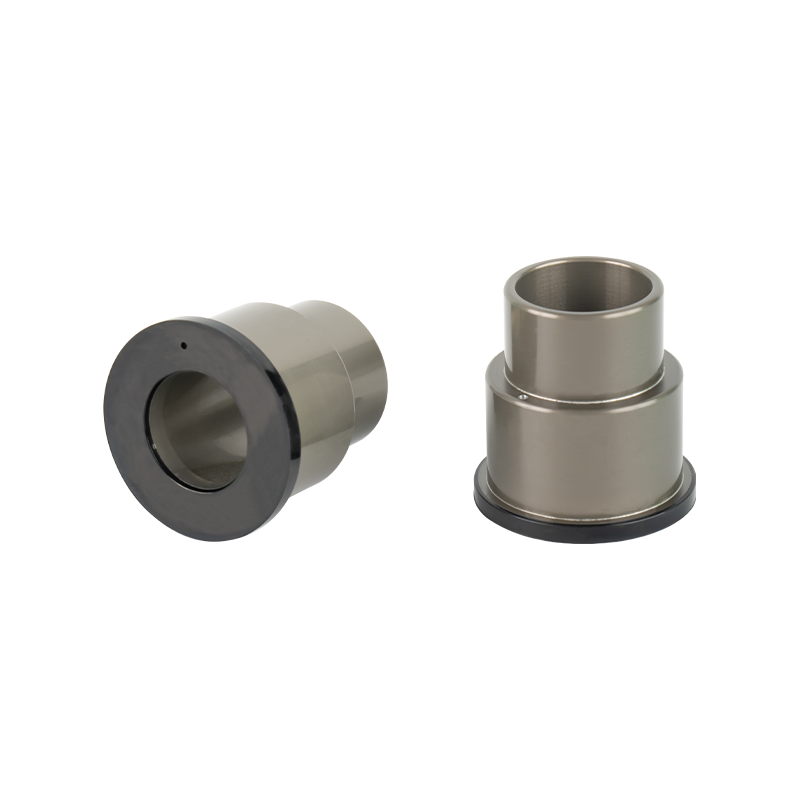

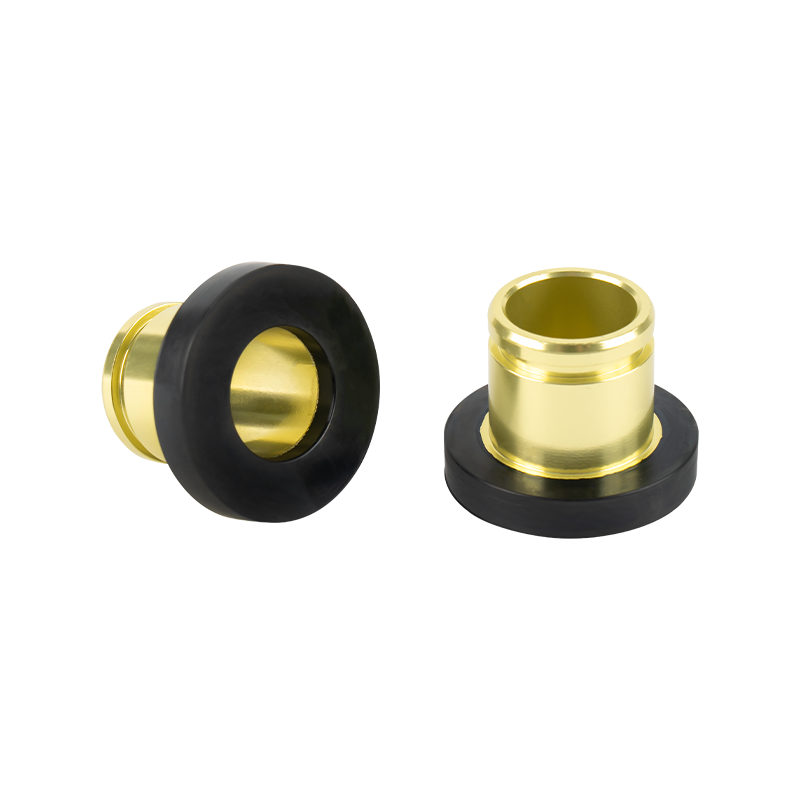

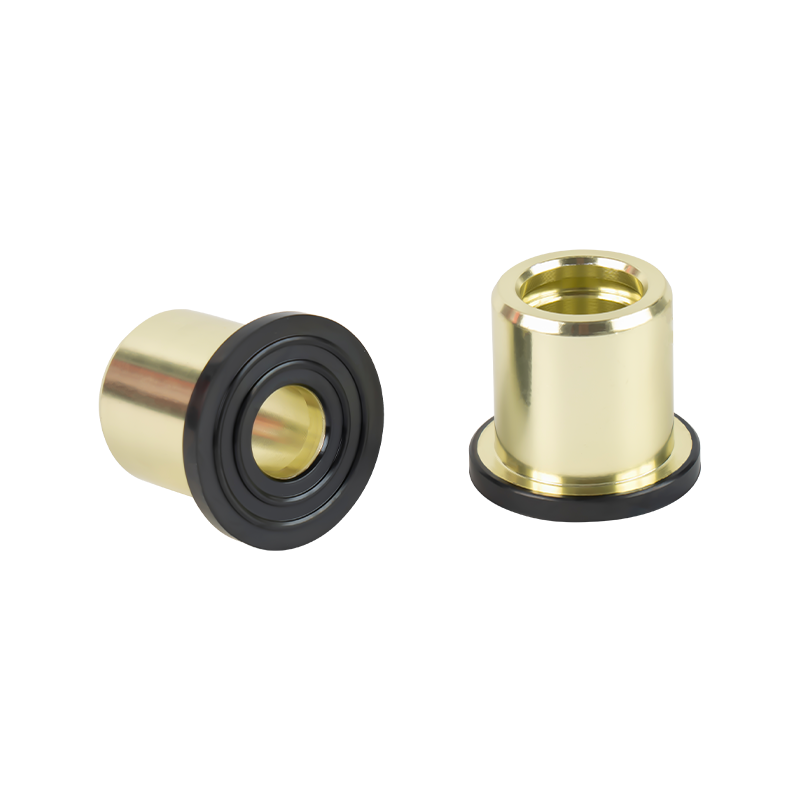

Key Component - Valve Seat:

The valve seat is a seemingly small yet critical precision component within the air brake valve. Typically made of high-performance engineering plastics or special alloys, it is responsible for:

Forming a sealing surface: It works with the valve core to prevent compressed air leakage in the closed state and maintain system pressure.

Precisely controlling airflow: In the open state, its structure influences the shape and size of the airflow path, directly impacting the valve's response speed, flow characteristics, and stability.

Withstanding high-frequency shock: The valve seat is subject to constant impact and wear during the frequent opening and closing of the valve core. Its durability, sealing, and dimensional accuracy directly determine the reliability, service life, and braking performance of the entire air brake valve. Even the slightest flaw can cause brake lag, air pressure leakage, or even brake failure, posing a serious threat to driving safety.

High Manufacturing Requirements:

Given the central role of air brake valves in vehicle safety, the production and manufacturing of their precision components, such as valve seats, places extremely stringent demands on their performance:

Stable material properties: They must withstand high and low temperature fluctuations, oil corrosion, long-term pressure shock, and wear.

Extreme dimensional accuracy: Micron-level tolerances ensure a perfect seal and stable flow characteristics.

Consistency: In large-scale production, every product must meet the same performance standards.

Strict quality control: Throughout the entire process from raw material processing to processing and testing.

Manufacturer Qualifications:

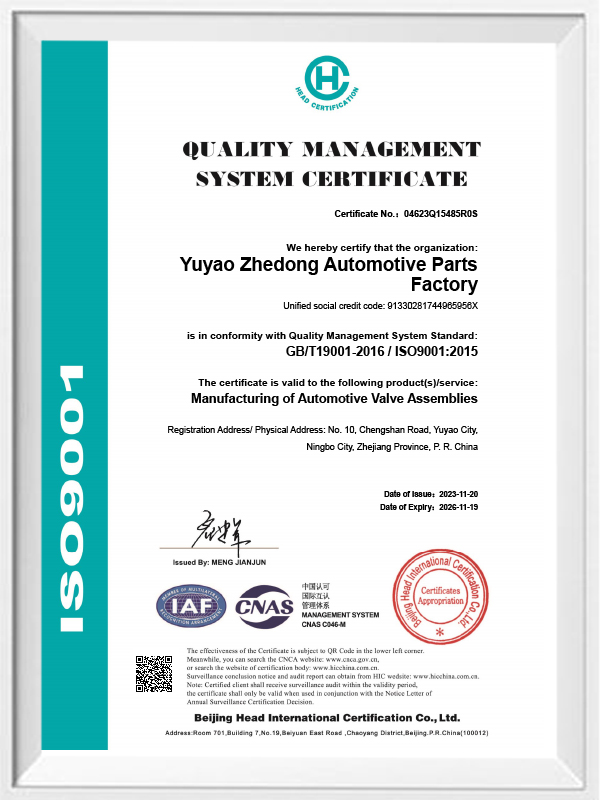

With many years of experience in the automotive brake field, Yuyao Zhedong Automotive Parts Factory Co., Ltd. (established in 1988) specializes in providing core precision components for commercial vehicle air brake systems. We deeply understand the importance of key components, such as valve seats, to brake safety and have established a comprehensive quality assurance process through:

ISO 9001 quality management system certification.

Professional mold manufacturing and material application capabilities ensure stable and reliable product performance.

We have extensive experience serving major domestic commercial vehicle and parts manufacturers (such as FAW, Second Automobile Works, and Wanxiang). We are committed to providing high-precision, high-durability, and high-consistency valve seat solutions to air brake valve manufacturers, becoming a trustworthy link in the chain of ensuring driving safety.

English

English русский

русский 中文简体

中文简体

02 Feb 2026

02 Feb 2026